When the stuck pipe ceases operation, A-One Oil Tools and Equipment Services Company can reduce the high cost of non-productive downtime. By using the Magnetic Stuck Point Logging Tool (MSPL43C) that measures in a single pass, it can detect changes in the magnetic permeability of the casing material, quickly and accurately providing the location of the blockage, which differs from the traditional method of repeated start-stop measurements. The tool has a unique design concept, brand-new signal-to-noise ratio (SNR) electronic equipment, and a fully high-configured acquisition module and algorithms, thereby enabling the MSPL to be flexibly used for a wide range of assessment applications in different testing environments.

Features:

. The tool can perform continuous measurements within the drill pipe (casing), which greatly enhances the efficiency of

well logging, and is highly effective compared to traditional point-by-point pipe inspection tools.

. The tool can quickly and accurately determine the location of blockages in high-angle or horizontal wells through a single logging process,

making it suitable for high-strength alloy pipes and coated pipes.

. The tool features a fully redundant structure with mutual isolation, ensuring safe and reliable completion of each testing task.

. The tool can be delivered to the horizontal section for blockage testing via cable pumping, continuous tubing, and sucker rod.

. It can reliably operate through difficult pipe runs to complete testing, without the need to deploy anchors as required by traditional

pipe inspection tools.

Applications:

The Tool can be used in conjunction with a variety of cutting tools

. Pyrotechnic cutting

. Chemical cutting

. Mechanical cutting

. Hydraulic cutting

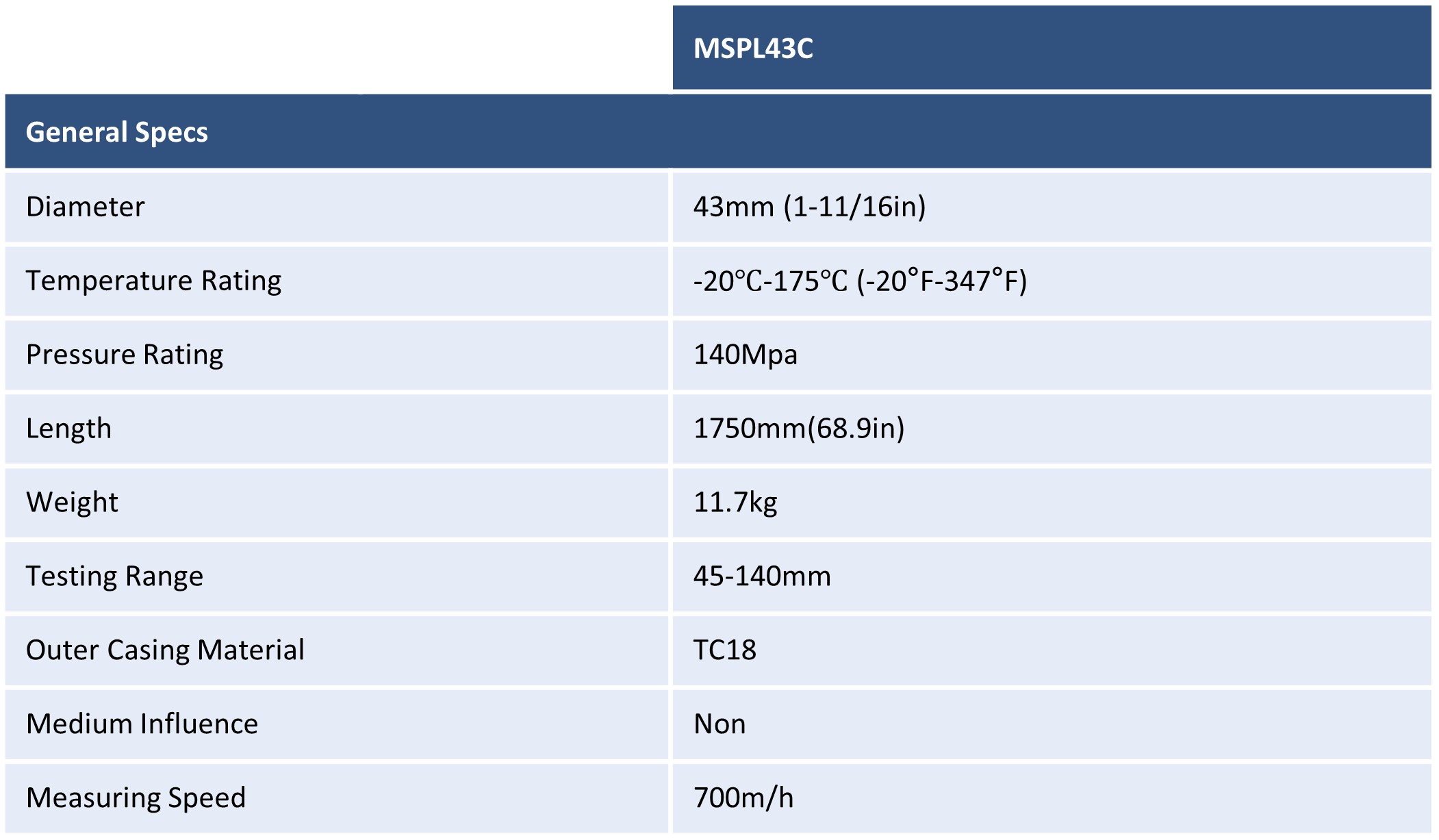

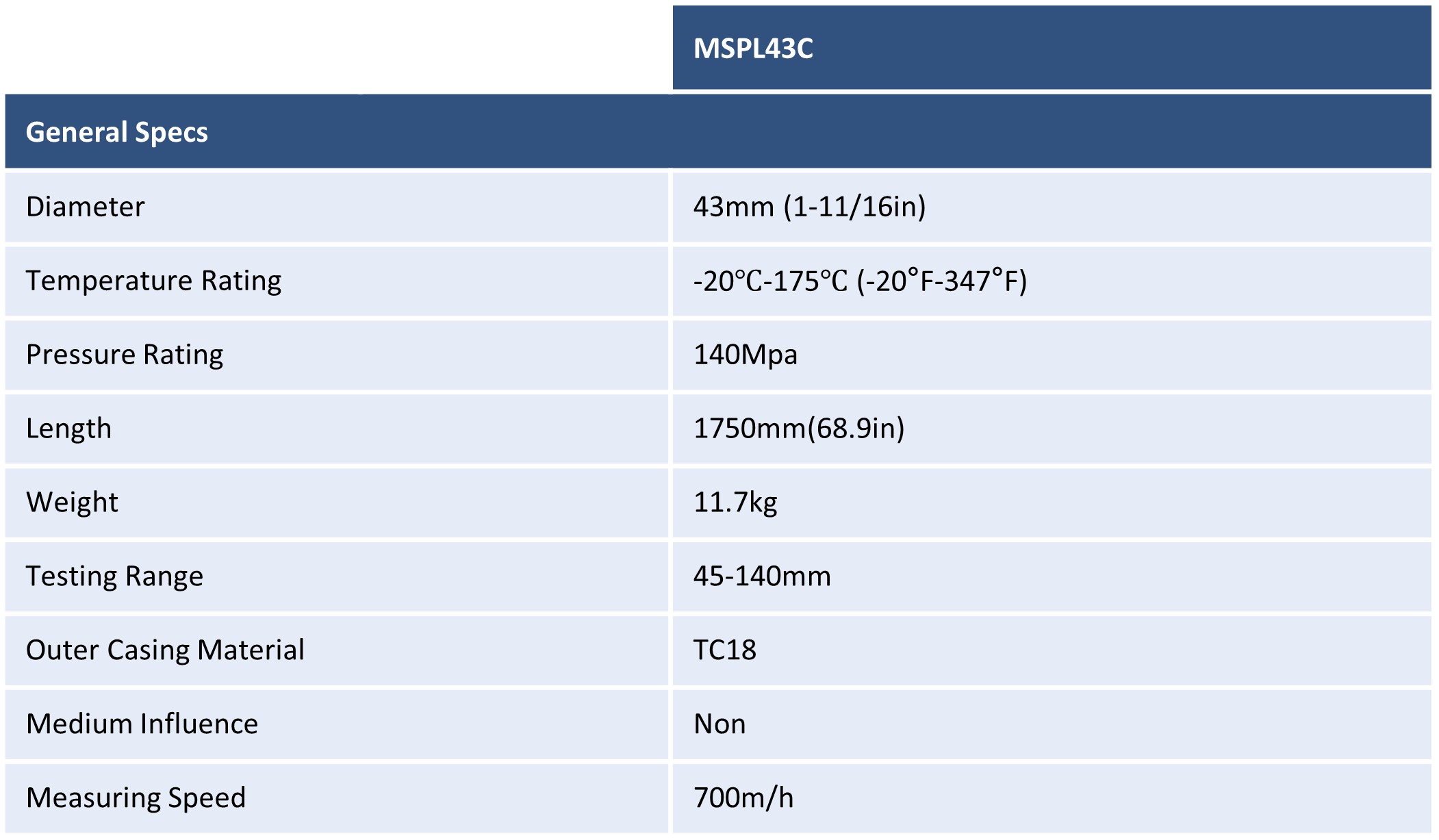

Specifications:

![]() Magnetic Stuck Point Logging Tool (MSPL43C).pdf

Magnetic Stuck Point Logging Tool (MSPL43C).pdf