The Electro-Magnetic Flaw Detector Tool (EMFD43C) is an electromagnetic corrosion measurement tool with an outer diameter of 43mm, capable of being operated through the casing. It has the unique ability to simultaneously inspect the casing and up to 3-4 layers of tubing behind it. There is no need for costly well workover equipment, nor is there a need to disassemble the completion tubing in a time-consuming and laborious manner, as the integrity of the casing string can be assessed. The new generation of magnetic thickness and damage logging tool can evaluate the quantitative thickness measurements and damage detection of up to four concentric tubes. The advanced tool combines a high-power transmitter, improved signal-to-noise ratio (SNR) electronic equipment, and a fully high-configured acquisition module and algorithms. This flexible approach allows for a wide range of assessment applications in different testing environments.

Features & Applications:

. The tool operates in a dense interval mode, capable of displaying up to 127 test curves, and utilizes a brand-new graphical

algorithm to present the test curves in the form of a spectrum.

. The Tool is equipped with a 13-core quick connector, which allows for convenient and rapid connection with

instruments such as Gamma, Well Temperature, CCL, Multi-arm Imaging Caliper, Memory Cement Bond Imaging Logging

Tool and the Downhole "Eagle Eye".

. With a small diameter, allowing it to be tested through casing/pipe.

. It can test multiple layers of casing, up to 3-4 layers of tubing.

. The tool has an integrated data memory function, enabling it to test highly-deviated and horizontal wells.

. It has no sensitive requirements for the medium inside the test well, offering a wide range of adaptability.

The Electro-Magnetic Flaw Detector Tool (EMFD43C) features a set of short ("C") and a set of long ("A") sensors. The instrument operates on the principle of transient electromagnetics, where the transmitting probe conveys high-energy electromagnetic pulses into the surrounding tubing. Based on the physical principles of pulsed eddy currents (PEC), the tool records the composite attenuation of the eddy current signals. These signals are then used to assess the condition of the pipe.

The long sensor records up to 127 channels, with decay times ranging from 1ms to 280ms. This captures the rapid attenuation signals of the far-field signals from alloy pipes to large casings. The short sensor has a smaller measurement aperture and a higher vertical resolution for scanning the inner pipe.

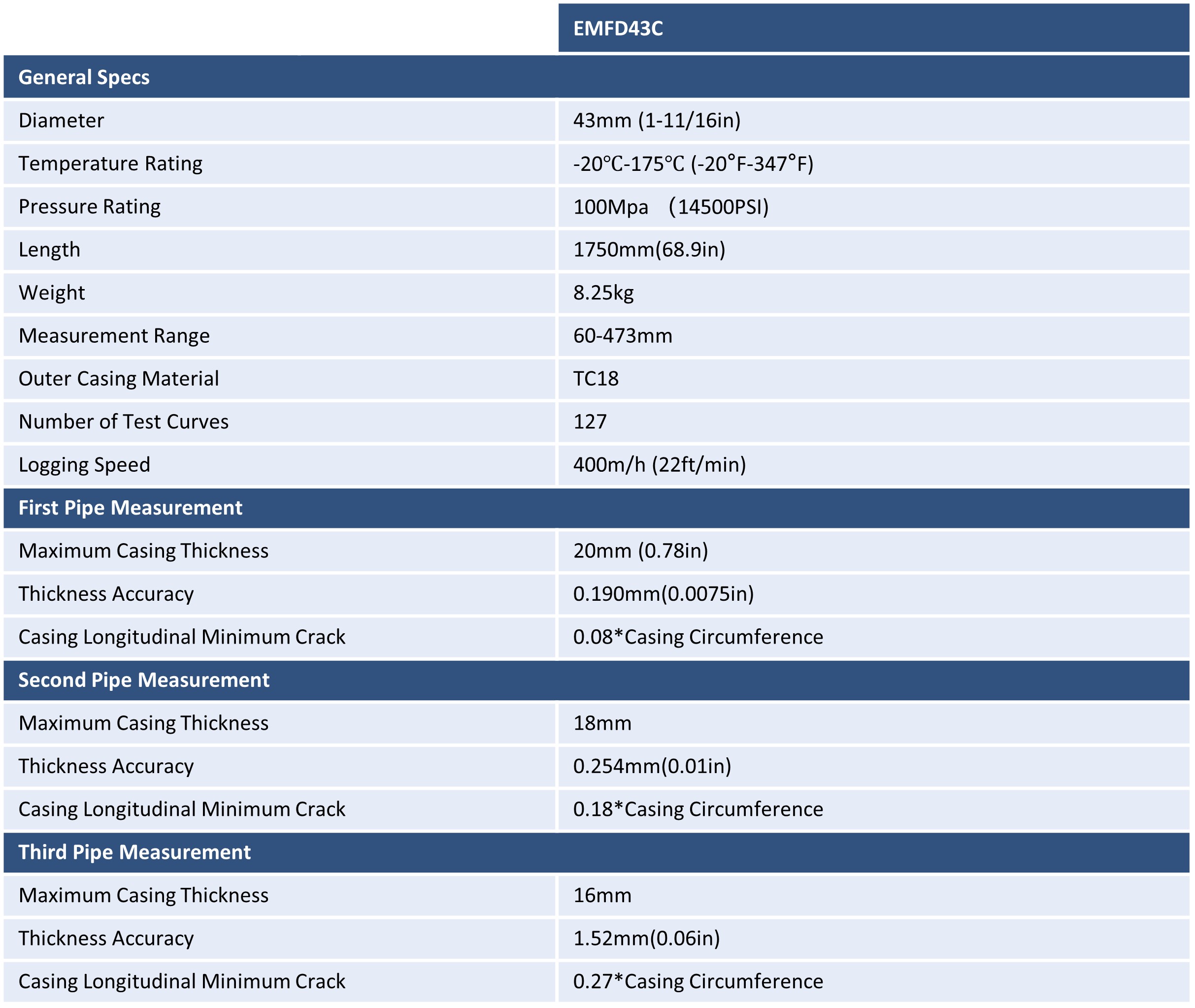

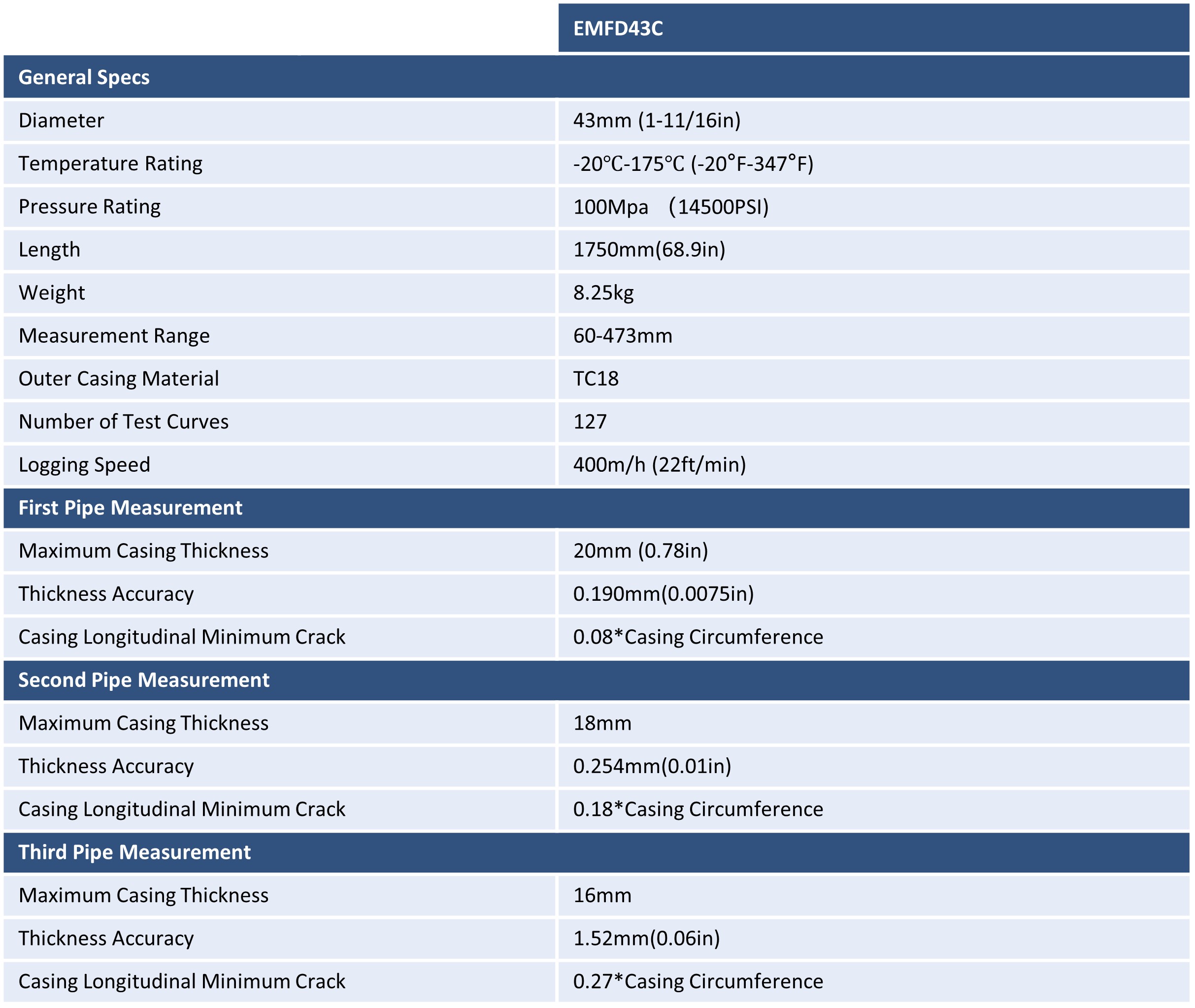

Specifications:

![]() Electro-Magnetic Flaw Detector Tool (EMFD43C).pdf

Electro-Magnetic Flaw Detector Tool (EMFD43C).pdf